What Are UV Transfer Stickers? Applications and Benefits

UV transfer stickers, also known as UV-cured transfer decals, are a type of adhesive decoration that uses ultraviolet (UV) light to cure and bond the design onto a surface. These stickers are widely used in industries such as automotive, electronics, cosmetics, and promotional products due to their durability, high-resolution printing, and versatility.

How Do UV Transfer Stickers Work?

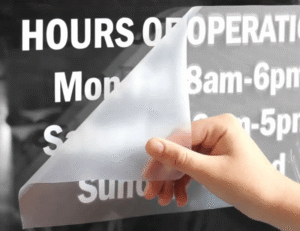

The production process involves printing a design onto a special film using UV-curable inks. Once printed, the design is coated with an adhesive layer and then exposed to UV light, which instantly hardens the ink. The sticker can then be transferred onto various surfaces, including plastic, metal, glass, and even curved objects.

Key Benefits:

-

Durability – Resistant to scratches, water, and fading.

-

High Precision – Allows for intricate designs and fine details.

-

Fast Production – UV curing is almost instantaneous.

-

Versatility – Works on multiple surfaces.

-

Eco-Friendly – UV inks contain fewer volatile organic compounds (VOCs).

Applications:

-

Automotive: Dashboard labels, interior/exterior decals.

-

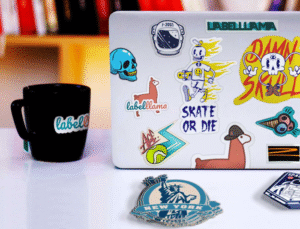

Electronics: Brand logos on smartphones, laptops.

-

Cosmetics: Luxury packaging decorations.

-

Promotional Items: Customized merchandise like mugs and phone cases.

UV transfer stickers offer a cost-effective and high-quality solution for branding and decoration, making them a popular choice in many industries.

Add comment